Prefilled filter/screen pipe

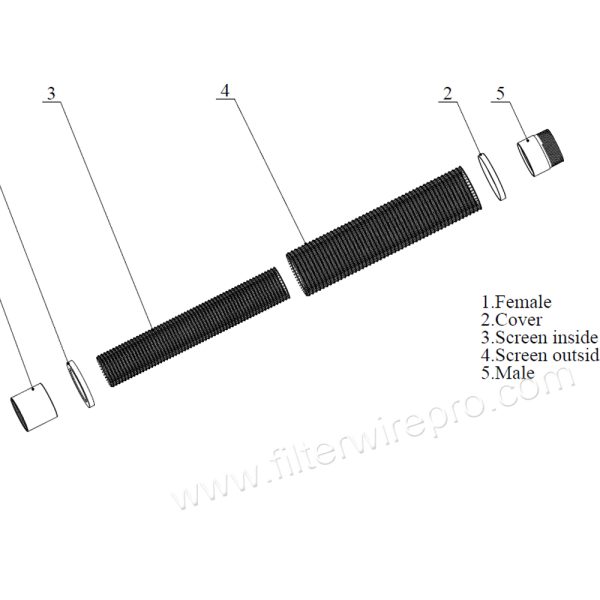

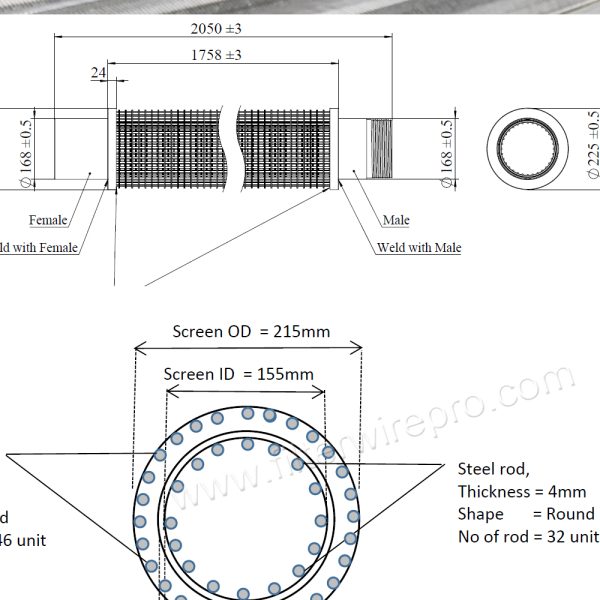

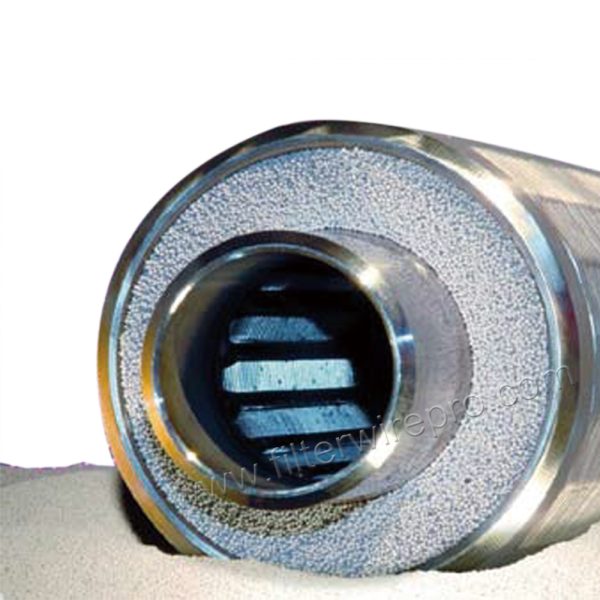

The pre-filled filter screen tube adopts a structure of “stainless steel metal base tube + ceramic ball pre-filled filter layer”:

Pre-filled filter layer: ceramic balls as the core filter material (without resin bonding) are filled between the base tube and the outer protective mesh to form a high-precision filter medium;

| Project | Typical Parameters |

| Pipe Diameter | 4.5 inches ~ 9.625 inches (suitable for different wellbore sizes) |

| Filtration Accuracy | 50μm ~ 300μm (customizable according to formation sand particle size) |

| Operating Temperature | -40℃ ~ 150℃ (suitable for conventional oil and gas well environments) |

| Operating Pressure | 35MPa ~ 105MPa (suitable for high-pressure wells/ultra-deep wells) |

| Ceramic Ball Material | High-alumina ceramic (wear-resistant, chemically resistant) |

| Applicable Well Depth | 0 ~ 7000 meters (onshore/offshore oil and gas wells) |

Application Scenarios

Pre-filled screens are primarily used in the “well completion sand control” stage of oil and gas wells. Applicable scenarios include:

1. Loose Sandstone Oil/Gas Wells:

When the formation is loose sandstone, formation sand is easily produced with the fluid. This screen can intercept formation sand, preventing sand from burying the production tubing and abrading surface equipment.

2. Horizontal Wells/Extended Distance Wells:

The formation stability of horizontal well sections is poor. The “ready-to-use” characteristic of pre-filled screens reduces the operation time in horizontal sections and lowers the risk of tubing jamming.

3. High Sulfur/High Salinity Wells:

The ceramic balls are resistant to chemical corrosion and suitable for use in acidic wellbore environments containing H₂S and CO₂, preventing the filter layer from corroding and failing.

4. Heavy Oil Thermal Recovery Wells:

Capable of withstanding thermal recovery temperatures of 150℃, suitable for sand control filtration in heavy oil development processes such as steam drive and SAGD.

Core Advantages (According to Contractor/Owner Needs)

1. For Contractors:

– No Well Enlargement Required: Customizable to client specifications;

– Reduced Operation Time: Pre-filled design eliminates the need for on-site filter material filling, reducing drilling/completion time by 1-3 days per well;

– Accelerated Development Pace: Simplified completion process facilitates earlier production of oil and gas wells.

2. For Owners:

– Low Maintenance Costs: Ceramic balls are less prone to scaling and biofilm contamination, with a screen life of over 50 years (compared to approximately 35 years for traditional resin screens);

– Long-Term Economic Efficiency: Reduces well workover frequency and lowers manpower and equipment investment for subsequent sand control maintenance.