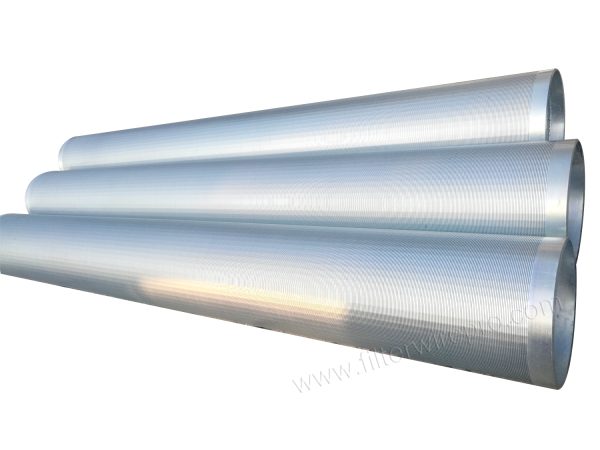

Precision Johnson-Type Wedge Wire Screens

The Gold Standard for Advanced Solid-Liquid Separation

Our Johnson Screens (also known as Wire-Wrapped Screens) represent the pinnacle of filtration technology. Utilizing a unique V-shaped profile wire and an all-welded construction, these screens are engineered for industries where precision, durability, and high flow rates are non-negotiable.

Core Technological Advantages

1. Anti-clogging V-shaped Wires

Unlike traditional mesh or perforated tubes, Johnson wire mesh uses V-shaped wires, creating a continuous slit that gradually widens inwards. This design ensures that particles have only two contact points with the mesh surface, allowing them to pass through smoothly without getting stuck, thus virtually eliminating clogging and downtime.

2. Maximum Hydraulic Efficiency (High Aperture Ratio)

Compared to standard mesh or perforated tubes, the continuous slit design provides a higher aperture ratio. This results in the following advantages:

Lower pressure drop: Higher throughput, lower energy consumption.

Reduced inlet velocity: Minimizes erosion and extends the life of the screen and surrounding equipment.

3. Superior Structural Integrity

Each intersection of the V-shaped wire and the internal support rod is induction welded. This forms a robust, high-strength “cage” structure capable of withstanding the extreme mechanical stresses, high collapse pressures, and thermal expansion in deep well or high-pressure reactor environments.

4. Absolute Gap Precision

Our advanced CNC welding technology allows us to control the gap width with extreme precision (down to 50 microns). This ensures consistent filtration performance and reliable particle retention throughout critical processes.

Key Specifications

Materials: SS304, 316L, Hastelloy, and other specialty alloys.

Gap Size: From 0.05 mm (50 microns) to 15 mm.

Diameter: Customizable, from 25 mm to over 1200 mm.

End Connections: Threaded connections (NPT/API), welded rings, flanges, or custom fittings.

Key Applications

Water Wells and Geothermal: Sand control and aquifer protection. Petrochemicals and Refining: Catalyst support grids and discharge collectors.

Mining and Aggregates: Large-capacity dewatering and screening.

Food and Beverage: Saccharification tank screens and juice filters.

Wastewater Treatment: Rotary drum screens and inlet systems.

At YZ Filter, we don’t just manufacture screens, we provide solutions. Every Johnson screen is custom-made to your specific process flow diagram (P&ID) or technical drawings, ensuring perfect integration with your existing containers or equipment.