High-Precision Stainless Steel Wedge Wire Strainer Nozzles

Engineered for Uniform Flow Distribution & Superior Media Retention

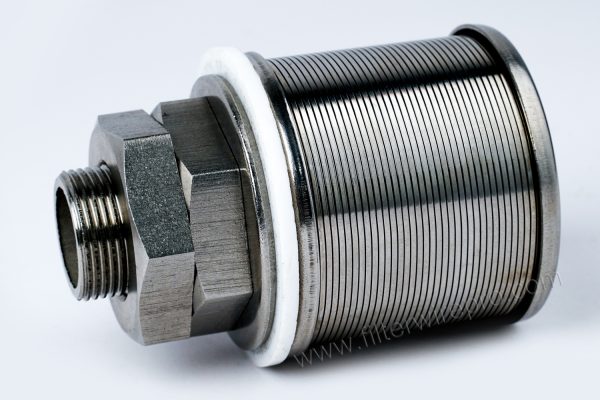

Our Wedge Wire Strainer Nozzles (also known as Water Caps or Header Nozzles) are critical components in professional water treatment and liquid-solid separation systems. Featuring an all-welded V-wire construction, these nozzles are engineered to provide a reliable, non-clogging barrier that ensures uniform flow patterns and protects expensive filter media or resins from escaping.

Technical Advantages & Product Excellence

- Self-Cleaning V-Wire Geometry: The precision-wound V-shaped wire creates a continuous slot that widens inwardly. This ensures that particles only have “two-point” contact on the surface, allowing them to pass through or be easily backwashed, virtually eliminating the risk of clogging.

- Exceptional Structural Integrity: As shown in our product imagery, every intersection of the wedge wire is induction-welded to the internal support structure. This creates a high-strength, rigid component capable of withstanding significant pressure differentials and mechanical stress without distorting.

- Uniform Flow & Pressure Management: Designed for optimal hydraulic performance, our nozzles ensure a balanced distribution of liquid or gas across the entire filter bed. This prevents “channeling” and maximizes the efficiency of your ion exchange or filtration process.

- Precision Slot Control: Utilizing advanced CNC winding technology, we offer slot tolerances as fine as 0.05mm. This level of precision is essential for retaining fine-grain resins and specialized filter media.

Technical Specifications

Feature | Specifications |

Common Materials | SS304, SS316L, 904L, Duplex 2205/2507, and Hastelloy |

Standard Slot Sizes | 0.05mm to 0.5mm (custom sizes available) |

End Connections | Male/Female Threads (NPT, BSP, G), or specialized bayonet mounts |

Components Included | Precision nozzle body, hexagonal tightening nut, and durable sealing gasket |

Flow Orientation | Out-to-In (Standard) or In-to-Out for specialized collectors |

Primary Applications

- Ion Exchange Systems: Perfect for softener beds, demineralizers, and condensate polishers.

- Sand & Carbon Filtration: Uniformly collects filtered water while retaining fine sand or activated carbon.

- Resin Traps: Installed in-line to prevent catastrophic resin loss in the event of primary screen failure.

- Underdrain Systems: For municipal and industrial water treatment plants.

- Chemical Reactors: Ensuring even distribution of reactants through catalyst beds.

At YZ Filter, we understand that flow rates and pressure drops are unique to every system. We offer fully customizable nozzle lengths, diameters, and slot configurations. Whether you are performing a maintenance replacement or designing a new vessel, our engineering team can provide the exact flow calculations and CAD support you need.